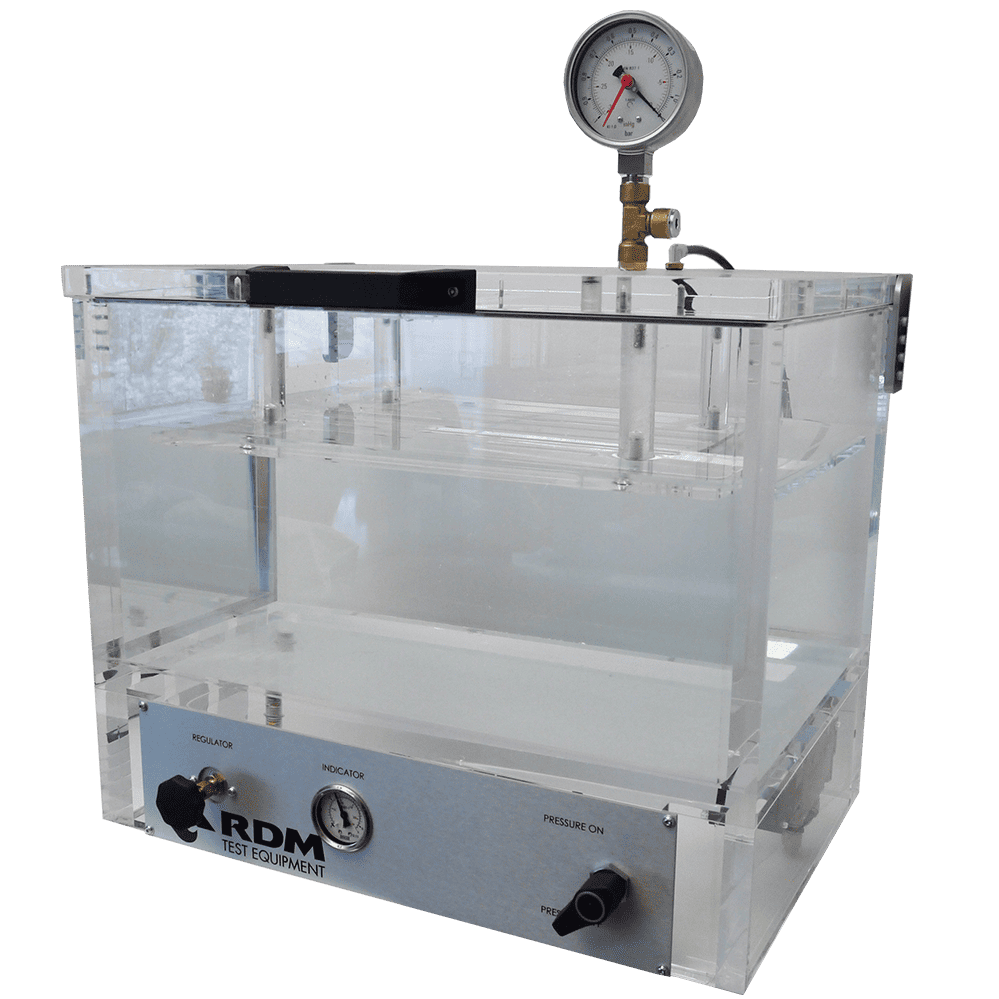

| The BLT leak tester uses a regulated pressure to 850 mbar to test The integrity of sealed packs. Convenient, easy to use and quick to test single or multiple packs.

Sealed packs are placed into the bubble leak tester water bath, a soft close hinged lid submerges them below the water level. An isolation switch is

opened causing the pack internal pressure to increase to the pre-set pressure. The operator observes the packs through the chamber

walls, a steady stream of bubbles indicates the location of any leaks. Burst testing can be conducted by gradually increasing the

pressure and observing the pressure gauge when the pack opens.

Features & Benefits

- Leak / Seal integrity tests to pre-set pressures.

- Burst testing to determine seal strength.

- No trace gas in pack needed, no mains electric, semi-portable.

- Simple & fast for quality control.

- Drain / Fill valve, convenient for regular change of water.

- Various water tank sizes

Also available is the BLT-P range which tests the integrity of sealed pack using a positive pressure via a needle / tube inserted in a pack. This alternative model meets standard ASTM F2096.

Technical Specification

| Model |

Internal Chamber

Dimensions (mm) |

Specification |

| BLT-V400 |

420(L) x 320(W) x 300(H) |

Bubble Leak Tester to test the

integrity of sealed packs using

compressed air through a

venturi valve producing vacuum

pressure from -100 to -850 mbar.

Includes water tank and bench

mounted stand, venturi vacuum

generator, precision pressure

regulator and gauge, isolation valve,

and water drain connector.

Requires clean, dry compressed

air, typically 6-8 bar. |

| BLT-V500 |

520(L) x 320(W) x 300(H) |

| BLT-V600 |

620(L) x 420(W) x 400(H) |

|