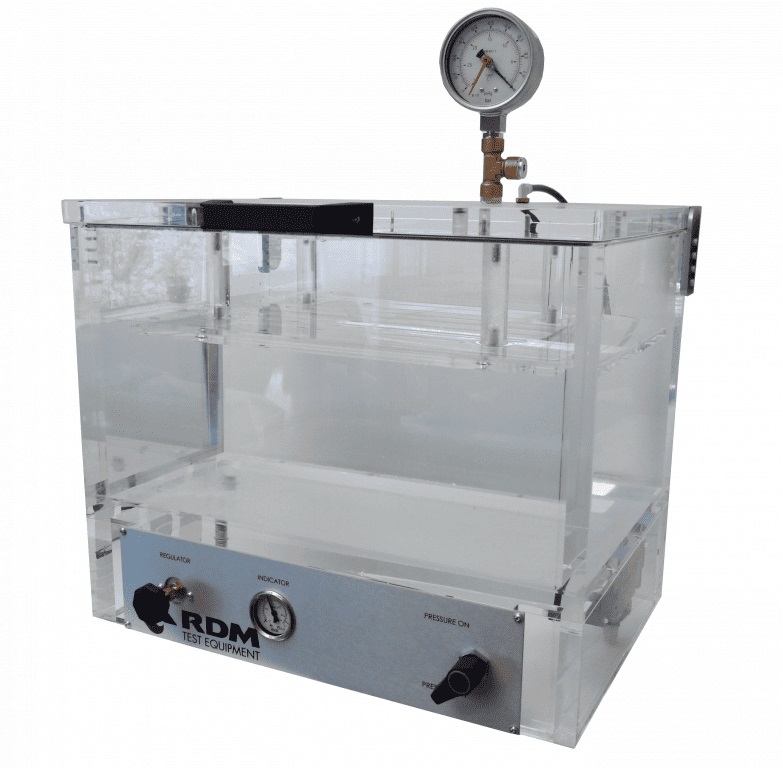

Bubble Leak Tester (BLT-P)

- Description

Sealed packs are placed into the bubble leak tester for positive pressure leak testing. A soft close hinged lid submerges the packs below the water level.

An isolation switch is opened causing the pack internal pressure to increase to the pre-set pressure. The operator observes the packs through the

chamber walls, a steady stream of bubbles indicates the location of any leaks. Burst testing can be conducted by gradually increasing the pressure and

observing the pressure gauge when the pack opens.

Features

- Leak / Seal integrity tests to pre-set pressures.

- Burst testing to determine seal strength.

- No trace gas in pack needed, no mains electric, semi-portable.

- Simple & fast for quality control.

- Drain / Fill valve, convenient for regular change of water.

- Various water tank sizes

For ASTM F2096, BLT-Pxxx is supplied with needle / septums. Includes dial pressure gauge, or upgrade to a digital pressure controller (Lippke 5000 with Bubble test method).

Technical Spec

| Model | Internal Chamber

Dimensions (mm) |

Specification |

| BLT-P400 | 420(L) x 320(W) x 300(H) | ASTM F2096 – Bubble Leak Tank to test the integrity of sealed packs using a positive pressure via a needle/tube inserted in a pack. Includes water tank and bench mounted stand, precision pressure regulator and dial gauge, isolation valve, and water fill/drain connector. Requires clean, dry compressed air, typically 6-8 bar. Upgrade to digital pressure controller (Lippke 5000) available. |

| BLT-P500 | 520(L) x 320(W) x 300(H) | |

| BLT-P600 | 620(L) x 420(W) x 400(H) |