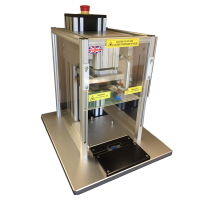

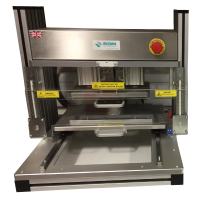

HT-1PC HOT TACK TESTER

- Description

- Application

Hot tack tester with manual sample loading and industrial pc for easy and repeatable measurement of hot tack seal strength of flexible films, to ASTM F1921.

HT-1 PC Hot Tack Seal Strength tester, with manual sample loading and

industrial PC for easy and repeatable measurement of hot tack seal strength to ASTM F1921.

Software Features User Interface

Graphical user interface operated from one main ‘Dashboard’ screen.

Touchscreen with optional use of keyboard and mouse.

15” tilting panel PC with Intel Atom CPU.

Comprehensive user access control for Engineer, Supervisor and Operator users.

Set Up

Parameter templates for Single, Replicate, and Sequential tests.

Save user defined parameter templates for later recall & re-use.

Define a variable parameter within a test series.

Add custom fields for traceability, e.g. batch number.

Choose results to be viewed in results table.

Measuring

Each series of tests saves to a single file, for a series of measurements.

Variable parameter (temperature, pressure, time) per file.

Exclusion of invalid measurements, Supervisor limited deletion.

Playlist of tests runs, manually controlled.

Rearrange, add or delete tests from playlist during measuring.

Analysis

Tabular view of measurement results.

View included and/or excluded results.

User definable columns in tabular view.

Export Reports Options

Export to Microsoft Excel® as .csv.

Export reports to pdf.

Print selected items as individual or batch reports and/or create pdf.

Print preview, with graph zoom and pan.

Features

• Flexibility and data integrity for 200 tests across 20 sealing settings, per study.

• Heat seal/peel graphs & trend graph for peak load & selected variable parameter: Jaw Temperature,

Pressure, Dwell, or Cooling Time.

• Easy operation via pre-set ‘Parameter Templates’ for Single, Replicate and sequential Tests;

simple to set-up, manual sample loading for versatile applications.

• ‘Playlist’ controls (like a music playlist) advances sealing conditions.

• PLC control of sealing & peeling parameters. Accurate PID temperature, precision load cells

for pressure and high speed peel measurement.

• Industrial PC, Windows 10 IoT, USB and ethernet connectivity. Export, print and create pdf

and csv files.

Sealing specification

Sealing Jaws: 2 x sealing jaws mounted within heater blocks with sensors and heaters.

Sealing Jaws: 25x50mm standard.

Sample width: max 30mm.

Sample thickness: max 1mm.

Sealing dwell time: 0.01 to 99.99s.

Sealing temperature: ambient to 250°C depending on sealing jaws.

Sealing pressure: 0 to 100psi.

Sealing pressure sensor: Pressure transducer.

Sealing temperature control: electronic PID.

Peeling specification

Cooling time: 0.01 to 99.9sec.

Peeling speed: 1 to 600mm/s.

Hot tack force measurement

Measurement range: 0 to 50N.

Sampling speed: max 500Hz depending on peel speed.

Number of readings: 2000 per measurement.

Sensor: strain gauge force transducer.

Software

Microsoft Windows®10 IoT preloaded on touchscreen pc.

Setting, storing and recalling of test parameters.

Storing, recalling and reporting of measured results.

Reporting

Measurement trend graphs: hot tack force vs temperature, pressure, dwell time, and cooling

time. Peak Load vs time.

Data Table: measured results, traceability data, date & time, variable parameter.

Outputs

USB and Ethernet connections.

Connections

Power: 85 to 250VAC, 50/60Hz 180VA.

Air supply: 6 to 8 bar clean dry compressed air.

Physical

Weight: 60kg. Size: 430W x 430D x 700H mm.

Design

Meets international standards including; ASTM F1921, DIN 55571.

Film clamps

Left and right pneumatic clamps synchronised with pulling operation.

Cold Peel

Allows seal to completely cool and cure before pulling operation takes place producing cold

seal strength measurement. Cooling Range – 0 to 99hrs 99mins 99sec.

Safety Guard

Micro-switch controlled guard in position feature.

Environment

5-50C ambient operating temperature,

RH 75% max (non-condensing).

Power

110V AC or 230V AC 50/60 Hz 1000W.

Accessories supplied

1000g calibration weight. 25mm x 350mm sample seal template.

Options available

Crimp jaws 25 x 50mm, 120 deg x 1.8mm pitch. Teflon coating to sealing jaws. Silicone rubber

covered lower jaw.

Made for current Industrial applications in FMCG, Plastic Films & Laminates, Convertors, R&D Labs etc.