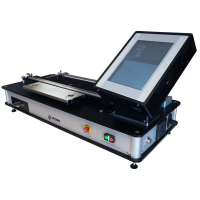

CF-400 Precision Friction Tester

- Description

Touch Screen Precision Friction Tester for determining Static and Kinetic Friction of packaging materials to ASTM, BS, ISO and TAPPI standards

The CF-400 Precision Co-Efficient of Friction Tester measures the static and kinetic friction properties of plastic films, foils, laminates, papers and boards. The equipment performs tests to recognised international test standards including ASTM D1894, ISO 8295, BS 2782 Method 824A, and TAPPI T549.

A Friction Tester is essential for measuring the slip properties of packaging materials to ensure smooth running on production packaging machines or to measure the effect that a coating or print has on base material

The CF-400 features the latest in design and technology for simple set up, testing, measurement and recording using a touchscreen display and data output via USB.

The constant smooth lead screw driven cross arm, standard base material with controlled surface roughness, and precision load cell ensures reliable and repeatable measurement.

Test results are displayed on the touchscreen for Static and Dynamic Friction, Active Force, Peak Force and Minimum Force in grams to 3 decimal places. During and after the test a test graph can be viewed. Test data is automatically saved with date/time stamp for download to .csv for further analysis. A standard Excel template can be used to process data for test reports.

Other benefits include: Quick action Spring Clamp for base sample material (optional vacuum channel clamp), easy fit sled with magnetic clamps for sample material, precision load cell with link connectors, standard base material with controlled surface roughness, optional replacement test beds in various materials, optional accessories for peel, tear and tensile tests.

CF-400 Precision Friction Tester meets the following standards: ASTM D1894, ISO 8295, BS 2782 Method 824A and TAPPI T549

Features & Benefits

Standard Accessories

• Test Sled, 200g, 63.5mm x 63.5mm. Other sizes available.

• Sled / Bed Cutting Templates.

• Check weight & pulley.

• Sled links.

Options

• Ski sled 100g for measurement of stainless steel on test material

• Bed replacements to give test comparison with different metals

• Tensile grips for T peel, tear or tensile test

• Peel attachment for 90° and 180° label / sticky tape peel test

Technical Specification

Test Bed: Natural anodised cast aluminium, 120mm x 420mm with maximum 150mm travel. Spring clamp fitted as standard, interchangeable with calibration pulley and optional peel/tear/tensile grips.

Test Area: 374 x 100mm

Test Sled: Anodised aluminium with foam contact pad. 200grams, 63.5 mm x 63.5mm (2.5” x 2.5”). Solid and cord links. Other sleds available.

Test Arm: Fitted with precision load cell, 2kg capacity. Link pin fitting interchangeable with optional peel/tear/tensile grips.

Speed Control: 10 – 1000mm/min + / – 1% FS

Motor Drive: DC synchronous motor driving ball screw and test arm.

Force: 0-1000 grammes +/- 0.25% FS. Active display on touchscreen.

Distance: 0 to 150mm + / – 1% FS. Active display on touchscreen.

Test Results: Static & Dynamic Friction (COF) calculated value 0.000 to 1.000 +/- 0.25% FS. Peak Force, Minimum Force.

Touch Panel Screen: 7” Touchscreen display Kinco HMI

16.77m (24 bits) True Colour

32-bit 792 Mhz Arm Risc CPU

Optional Vacuum Test Bed: If fitted, requires compressed air input pressure of 80 – 100 PSI, supplied to vacuum generator with on/off push button. Vacuum drawn on test bed to hold base sample.

Test Bed Temp: Ambient

Dimensions: 440 x 265 x 275mm approx. 25kg

Data Output: Data formatted to .csv output to USB

Power: 240 VAC single phase 50/60 Hz (110V AC available on request)

0.75 KW max

Environment: 5-35°C ambient operating temperature, RH 75% max (non-condensing)