TMI Bending Resistance Tester & Optional GraphMaster™ Software

INTRODUCTION

Model 79-25 is a user-friendly microprocessor controlled instrument to determine the bending resistance of paper, paperboard, plastic film, medical tubing, and wire. Bending stiffness is a characteristic associated with the rigidity of a material. This property is related to the modulus of elasticity of the material's stiffness. Our Bending Tester was originally developed to produce a more concise, consistent measurement for the paper industry. This property is now used in a variety of industries including personal products, paper, flexible films, packaging and non-wovens.

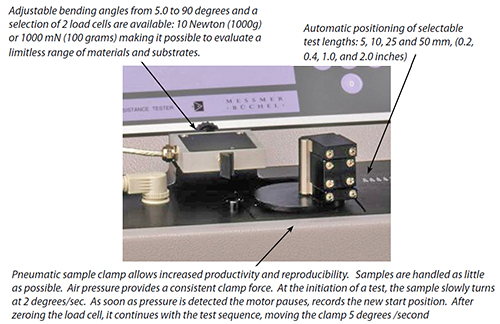

Our two-point method secures the specimen into a pneumatic clamp and bends the sample up to 90° against a force transducer.

What makes our Bending Resistance instrument so unique is its versatility and accuracy. Bending forces are measured at selectable bending angles from 5.0 to 90°. The instrument is available with a 100 or 1000 gram precision load cell. The advanced data acquisition system senses forces down to 0.5g. Materials can range from 5 to 50mm in length, up to 2.5mm thick.

BENEFITS

- Very flexible for performing different types of tests and for different standards.

- Pre-certified weights and sample cutter options

- Ability to add special formulas to meet unique bending stiffness requirements

- Competitive advantages for accuracy and usability

- Motorized testing and pneumatic clamping eliminates operator influence

SPECIFICATIONS

- Choice of 10N or 1000mN load cell

- Min. force sensitivity: 0.5mN with 1000mN load cell

- Selectable bending angle 5.0-90° and test length 5-50mm

- Meets ISO 2493, AS/NZ 1301-4535, BS 3748, DIN 53121, SCAN P29, TAPPI T556

- RS232 serial data output, printer output and analog signal output

- Can be directly calibrated to traceable National standards

FEATURES

- Direct sample to load cell contact for accurate measurement

- Easy selection of test parameters from a comprehensive range through a setup menu

- Motorized test length setting

- Pneumatic clamps with fast release provide consistent clamping pressures for fast, repeatable results

- Large, clear display showing peak value and angle

- Load cells are fitted with overload protection

- Direct data output via RS-232 to printer or optional GraphMasterTM analysis software

- Calculates Taber Stiffness, Youngs Modulus, Gurley Stiffness units.

- Can be directly calibrated to traceable national standards

STANDARDS

ISO 2493, AS/NZ 1301-4535, BS 3748, DIN 53121, SCAN P29, TAPPI T556

Can be directly calibrated to traceable national standards

INSTRUMENT SIZE

| |

Depth: |

|

330 mm (13 in.) |

| |

Height: |

|

180 mm (7 in.) |

| |

Width: |

|

330 mm (13 in.) |

| |

Weight |

|

15 kg (33 lb) |

CONNECTIONS

| |

Electrical: |

|

Specify voltage requirements when ordering |

| |

Air: |

|

(instrument quality) 400-600 kPa700 kPa (90 psi) max. supply pressure |

INCLUDED ACCESSORIES

- Clear plastic table for dead weight calibration

OPTIONAL ACCESSORIES

- Certified dead weight set to meet ISO requirements

- Sample Cutter

- Printer

ORDERING INFORMATION

| |

Load cell |

|

Catalog Number |

| |

10 N |

|

79-25 |

| |

1,000 mN |

|

79-25 (specify 1,000 mN) |

Download Brochure PDF